Three-proof fabrics represent a significant advancement in textile technology, combining fire resistance, waterproofing, and mildew prevention through the innovative use of nano-interface technology. At the heart of these high-performance materials lies a sophisticated treatment process that enhances fabric durability and functionality, meeting the demanding requirements of both professional and everyday applications.

Nano-interface technology works by applying an ultra-thin, stable layer of nanoparticles onto the surface of the fabric. This nano-coating is meticulously engineered to create a protective barrier that offers multiple benefits. The treatment starts with a process known as super double-thinning, which ensures that the nanoparticle layer is evenly distributed and securely bonded to the fabric fibers. This results in a fine, almost imperceptible coating that does not significantly alter the fabric’s natural feel or breathability.

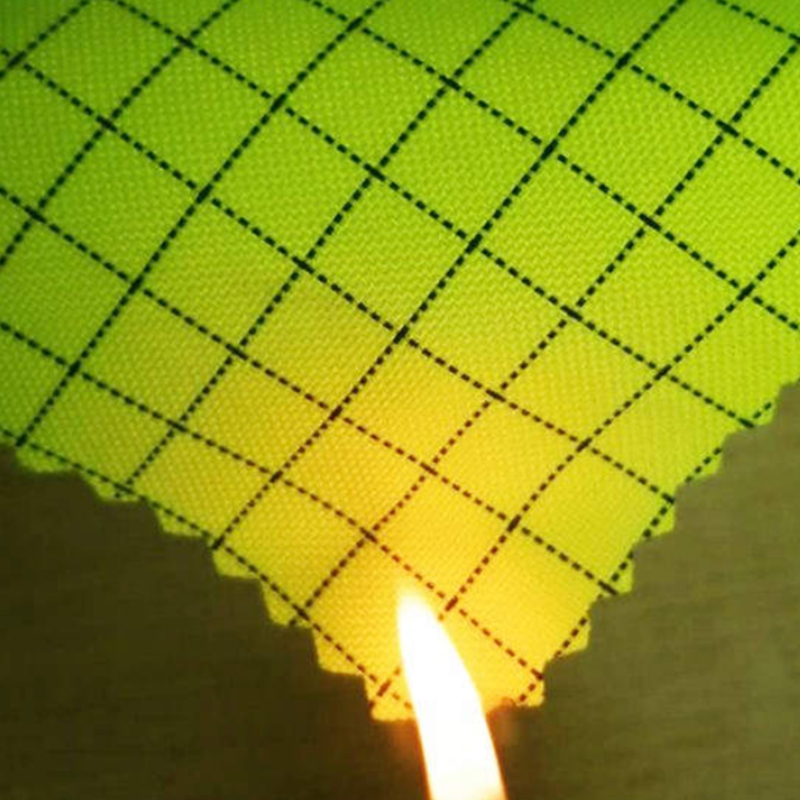

For fireproofing, the nanoparticles in the coating are designed to resist high temperatures and prevent ignition. These nanoparticles can act as thermal barriers or catalysts that inhibit the spread of flames, thus enhancing the fabric’s fire resistance. This makes three-proof fabrics ideal for use in protective clothing and equipment where exposure to fire is a risk. The waterproofing feature of the nano-coating involves creating a hydrophobic surface that repels water molecules, effectively preventing them from penetrating the fabric. This is achieved through the application of nanoparticles that create a stable air layer on the fabric’s surface, reducing surface tension and allowing water to bead off rather than soak in.

In addition to fire and water resistance, the nano-interface technology imparts mildew resistance. The nano-coating prevents the accumulation of moisture that can lead to mold and mildew growth, thus maintaining the fabric's hygiene and longevity. Furthermore, many three-proof fabrics are treated to resist oil and dirt. The nanotechnology used can include hydrophobic and oleophobic properties, which repel oils and prevent dirt from adhering to the fabric. This makes the fabric easier to clean and maintain, while also prolonging its lifespan.

The combination of these protective properties results in a fabric that is not only functional but also comfortable. Despite its advanced treatments, three-proof fabric maintains a natural softness and breathability, ensuring that it remains pleasant to wear in various applications. This unique blend of comfort and performance is made possible by the precise control of the nano-coating process, which integrates seamlessly with the fabric's inherent properties without compromising on flexibility or tactile qualities.

Nano-interface technology transforms ordinary fabrics into high-performance materials capable of withstanding challenging conditions. By utilizing nanoparticles to create a protective barrier, three-proof fabrics achieve a remarkable level of resistance to fire, water, mildew, oil, and dirt. This sophisticated approach to textile engineering enhances safety and durability, making three-proof fabrics valuable in both specialized industrial applications and everyday use.