Colorfastness, the ability of dyes to resist fading or bleeding when exposed to various environmental factors, is crucial for ensuring the longevity a...

READ MOREProduct category

Product category

-

190T Nylon spinning fabric

Nylon spinning is a type of silk fabric made of nylon filaments, also known as nylon spinning. There...Read More -

210T Nylon spinning fabric

Nylon spinning is a type of silk fabric made of nylon filaments, also known as nylon spinning. There...Read More -

210T Nylon jacquard fabric

210T Nylon jacquard is a fabric composed of a mixture of nylon and polyester fibers, which has stron...Read More -

200D Nylon jacquard fabric

200D Nylon jacquard is a fabric composed of a mixture of nylon and polyester fibers, which has stron...Read More -

210D 114T Nylon oxford fabric

210D 114T Nylon Oxford Fabric is the most representative nylon product of our company. Unlike ordina...Read More -

210D Nylon oxford fabric with increased density

210D Nylon Oxford Fabric With Increased Density is an encrypted nylon Oxford fabric produced by our ...Read More -

500D Nylon cordura fabric

500D Nylon Cordura Fabric is one kind of Nylon Cordura. Nylon CORDURA, originally produced by DuPont...Read More -

1050D Nylon cordura fabric

1050D Nylon Cordura Fabric is one kind of Nylon Cordura. In nylon Cordura, it belongs to the categor...Read More -

840D Nylon small double strand fabric

840D Nylon small double-strand Fabric is a kind of all-Nylon fabric, which is woven with Nylon filam...Read More -

1680D Nylon double strand fabric

1680D nylon Oxford fabric has a good glossiness and a smoother feel. Using 1680D nylon waterproof fa...Read More -

228T Matte nylon taslan fabric

228T Matte Nylon Taslan Fabric which is woven with Nylon filament. Taslon is a fabric woven from nyl...Read More -

320D Matte nylon taslan fabric

320D Matte Nylon Taslan Fabric which is woven with Nylon filament.Taslon is a fabric woven from nylo...Read More

Nylon Spinning/Jacquard/Oxford Fabric Manufacturers

About us

Anhui Liqiang Textile Technology Co., LTD

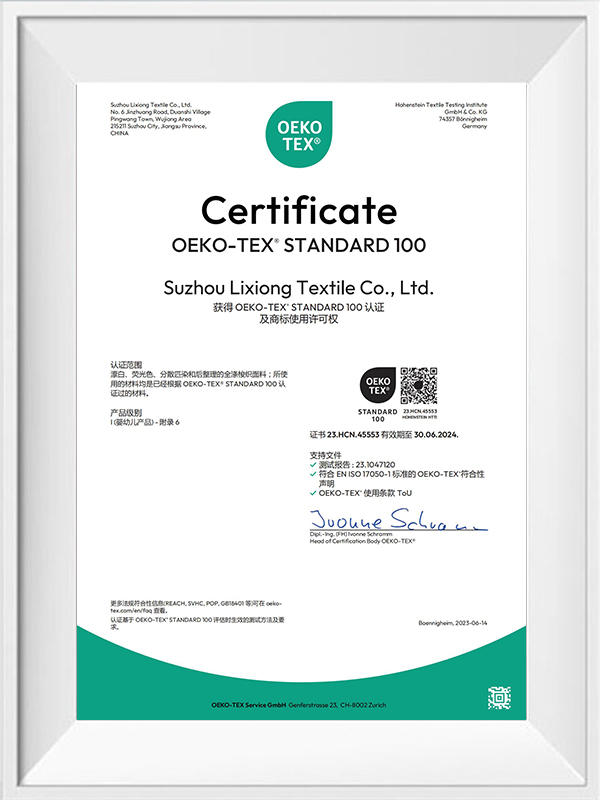

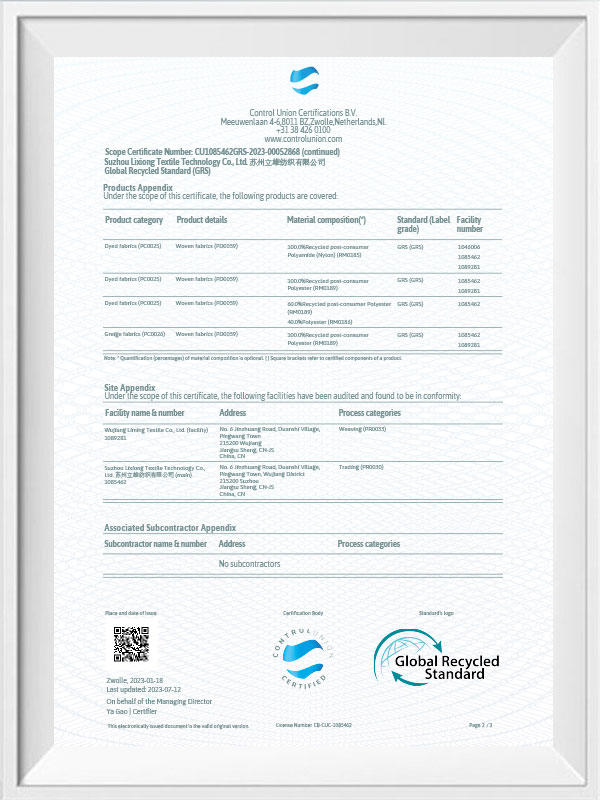

Suzhou Lixiong Textile Co., Ltd. is a combination of industry and trade enterprises, as a branch of Wujiang Liming Textile Co., Ltd., the company was initially established in the "silk capital"-Shengze, after the completion of the factory office building to move to Wujiang Pingwang. Mainly to luggage cloth and finished fabric sales. Our company cooperates with a number of well-known domestic luggage companies and includes a number of listed companies. With the expansion of the size of the company, the company's sales are also increasing, and production and sales are gradually closer to internationalization. At the end of 2018, Mr. Zhang Lianmin, chairman of our company, went to Langxi County, Anhui Province, bought 69000㎡ of land to expand production, established Anhui Liqiang Textile Technology Co., Ltd., and began to build the plant at the beginning of 2019. OEM Nylon Oxford Fabric Manufacturers and OEM Custom Nylon Jacquard Fabric Company in China. And in July 2020, 10 standard factories were completed and put into production, and the production capacity was significantly doubled.

Our company passed the GRS qualification certification in 2019, and devoted ourselves to the initial review stage of OK-TEX100 research and development. We will continue to expand and strengthen ourselves, and always stay at the forefront of the industry.With the expansion of market competitiveness, our company is also constantly improving and breaking through itself. On the basis of conventional Oxford cloth, polyester taffeta, pongee and jeanette, we are still researching and developing new varieties, trying to develop fabrics that are more contemporary and in line with the public's aesthetics.

News

-

-

Polyester filament fabric can be bleached or treated to achieve lighter or pastel colors, although the process may differ from bleaching natural fabri...

READ MORE -

Polyester elastic fabric has become a popular choice in clothing and textile industries due to its versatility, durability, and stretchability. Howeve...

READ MORE -

Polyester filament fabric is renowned for its quick-drying ability, making it a popular choice for activewear, outdoor gear, and various moisture-wick...

READ MORE

Nylon Fabric Industry knowledge

How abrasion resistant is nylon fabric compared to traditional fabrics?

Nylon fabric is generally more abrasion resistant compared to traditional fabrics like cotton, wool, or polyester. Nylon is a synthetic material known for its durability and toughness, making it an excellent choice for various applications where abrasion resistance is crucial.

The abrasion resistance of a fabric depends on several factors, including the specific type and construction of the fabric, the denier (thickness) of the nylon fibers, and any additional coatings or treatments applied to enhance durability. In general, Nylon Oxford Fabric tend to have a higher resistance to abrasion compared to natural fabrics like cotton and wool, which are more prone to wear and tear.

Moreover, nylon is commonly used in the manufacturing of outdoor gear, sports equipment, and heavy-duty workwear due to its high tensile strength and abrasion resistance. It can withstand repeated friction, making it less likely to develop holes, tears, or pilling, which are common issues with traditional fabrics.

How does the denier (fiber thickness) of Nylon Jacquard fabric affect its strength and durability?

The denier, which refers to the thickness or diameter of individual nylon fibers, significantly influences the strength and durability of nylon spinning fabric. Here's how denier affects these properties:

Strength:

Higher Denier: Nylon Spinning Fabric with higher denier fibers are generally stronger. The thicker individual fibers can withstand greater tension and stress without breaking. This makes higher denier nylon fabric suitable for applications where strength is a primary consideration, such as heavy-duty bags, backpacks, and industrial textiles.

Lower Denier: Fabrics with lower denier fibers are typically less strong than their higher denier counterparts. They may be suitable for lightweight and less demanding applications like sheer curtains or lightweight clothing.

Durability:

Higher Denier: Fabrics with higher denier nylon fibers tend to be more durable and resistant to abrasion and wear. They can withstand rough handling, friction, and exposure to the elements, making them suitable for outdoor gear, upholstery, and heavy-duty workwear.

Lower Denier: Fabrics with lower denier fibers are generally less durable. They may be more prone to pilling, snagging, and wear and tear, especially when used in high-stress situations. Lower denier nylon is often chosen for applications where weight and breathability are more critical than durability, such as lightweight clothing or sheer curtains.

Weight:

Higher Denier: Fabrics with higher denier fibers tend to be heavier due to the thicker individual fibers. This can be advantageous for applications where added weight is not a concern, or where the extra weight contributes to the fabric's strength and durability.

Lower Denier: Fabrics with lower denier fibers are typically lighter in weight. They are often chosen for applications where a lightweight and breathable fabric is preferred, such as activewear or summer clothing.